Battery Pouch Assembly

KRYLEX® Next Generation Battery Pouch Cell Bonding & Sealing

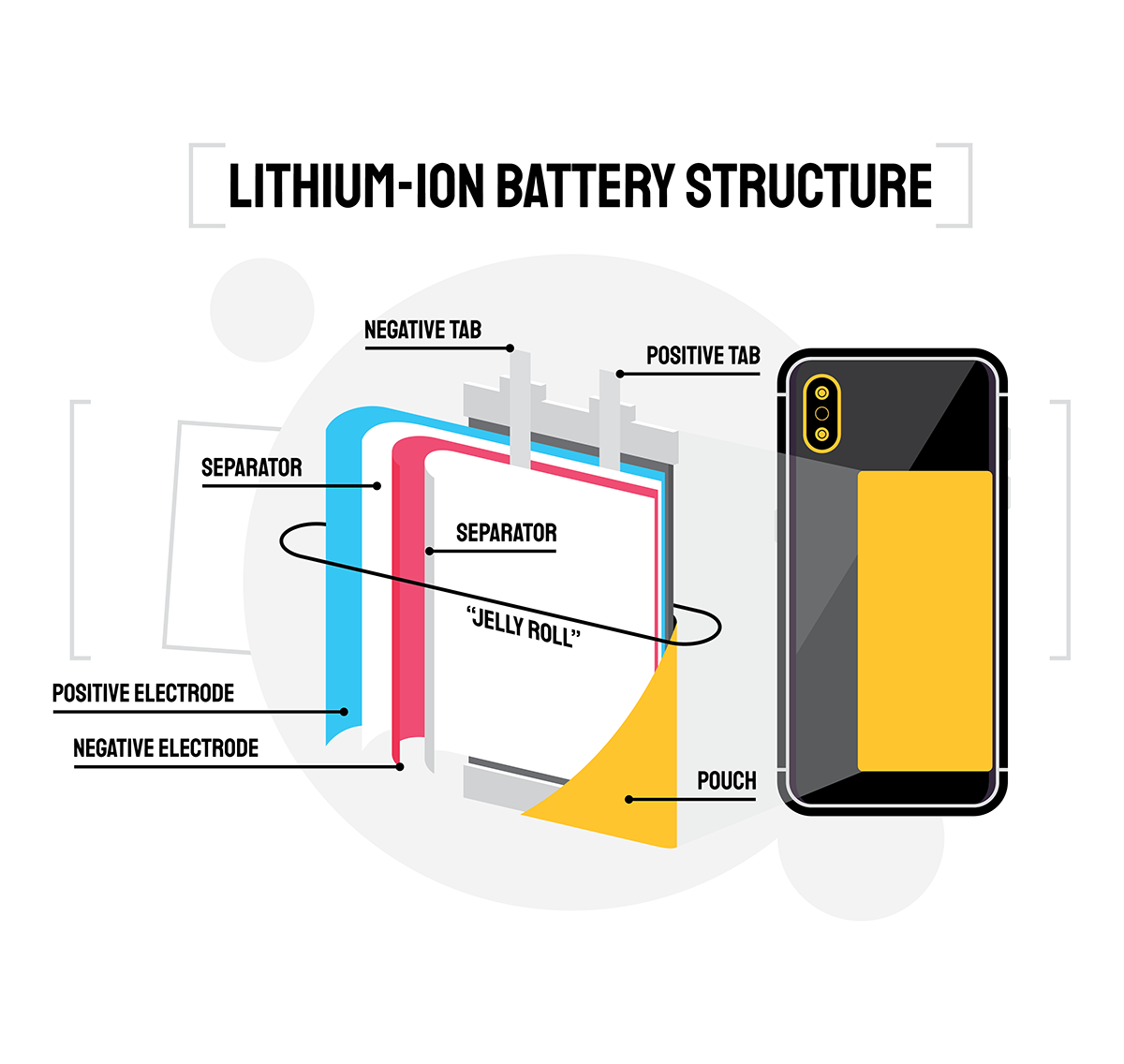

The pouch cell manufacturing process utilize adhesives in the construction of the final product to both bond and seal. KRYLEX® adhesives provide structural integrity and protect the module from any moisture intrusion or chemical leakages – preventing the inside of the battery from exposure to the environment. Critical performance characteristics of the adhesive and sealants include the ability to maintain proper seals while exposed to various conditions such as:

- Thermal cycling or thermal shock (temperature ranges of -40°C to 80°C)

- High humidity environments

- Mechanical forces seen during the life of the device such as vibration, impact, shear, and compression.

Battery Pouch Bonding

Hover over the targets to read more information

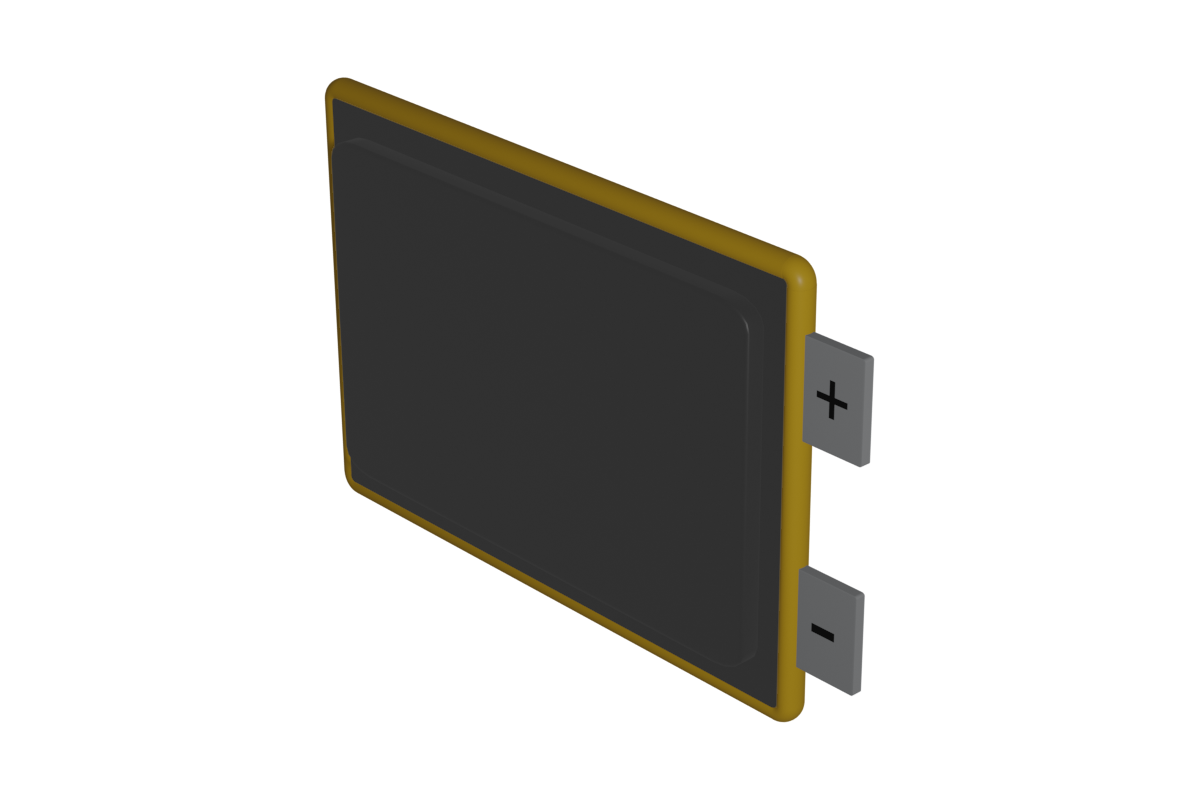

EDGE BONDING

EDGE BONDING

EDGE BONDING

KRYLEX® KU5100 series products are 1 part (pre-mixed) adhesive formulas designed to cure rapidly when exposed to the appropriate intensity of UV light. The products have optimized rheology to enable easy application by automated dispense equipment. Using KU5144 UV adhesive oppose to traditional tapes allows more space in the device or battery pack.

SEALANT

Sealants are used in the assembly of the battery case enclosure. KH9005 is used to protect the module from any moisture intrusion or chemical leakages, preventing the inside of the battery from exposure to the environment.

STRUCTURAL & REWORKABLE ADHESIVES

Structural adhsives are required to bond the battery pouch into the housing or frame of the device. KH9012 has high green strength, low bond-line bubble formation post cure and exceptional strength to metallic substrates. It is also reworkable which is helpful in post production.

EDGE BONDING

KRYLEX® KU5100 series products are 1 part (pre-mixed) adhesive formulas designed to cure rapidly when exposed to the appropriate intensity of UV light. The products have optimized rheology to enable easy application by automated dispense equipment. Using KU5144 UV adhesive oppose to traditional tapes allows more space in the device or battery pack.

SEALANT

Sealants are used in the assembly of the battery case enclosure. KH9005 is used to protect the module from any moisture intrusion or chemical leakages, preventing the inside of the battery from exposure to the environment.

STRUCTURAL & REWORKABLE ADHESIVES

Structural adhsives are required to bond the battery pouch into the housing or frame of the device. KH9012 has high green strength, low bond-line bubble formation post cure and exceptional strength to metallic substrates. It is also reworkable which is helpful in post production.

Benefits of KRYLEX® Battery Adhesives

KRYLEX® performance adhesives for pouch cells have led the shift away from tape adhesives to liquid-paste adhesives that are applied by an easy automated dispense process. These liquid adhesives, both PUR and UV Chemistries, have not only improved pouch cell manufacturability but have improved reliability and helped drive down costs and reduce wastage. KRYLEX® KU5100 series are ideal next generation Pouch Cell sealants, maximizing production efficiencies to work with new and developing pouch design technologies. KRYLEX® high-performance adhesives are at the top of the industry for current and next generation pouch cell sealing with benefits that include

- Ultra-rapid UV cure fixation

- Low shrinkage

- High reliability and structural integrity

- Reworkability