Automotive Adhesives

Automotive Industry

The automotive industry is in the middle of a revolution led by the surge in electric vehicles. Innovations in battery technology, autonomous driving, e-mobility and lightweight materials have completely changed the landscape of automotive manufacturing globally. The Chemence® experience developing and manufacturing adhesives and sealants for the traditional automotive industry as well as for high end electronics manufacturing has positioned us to deliver the ideal solutions portfolio for electric vehicle manufacturers today.

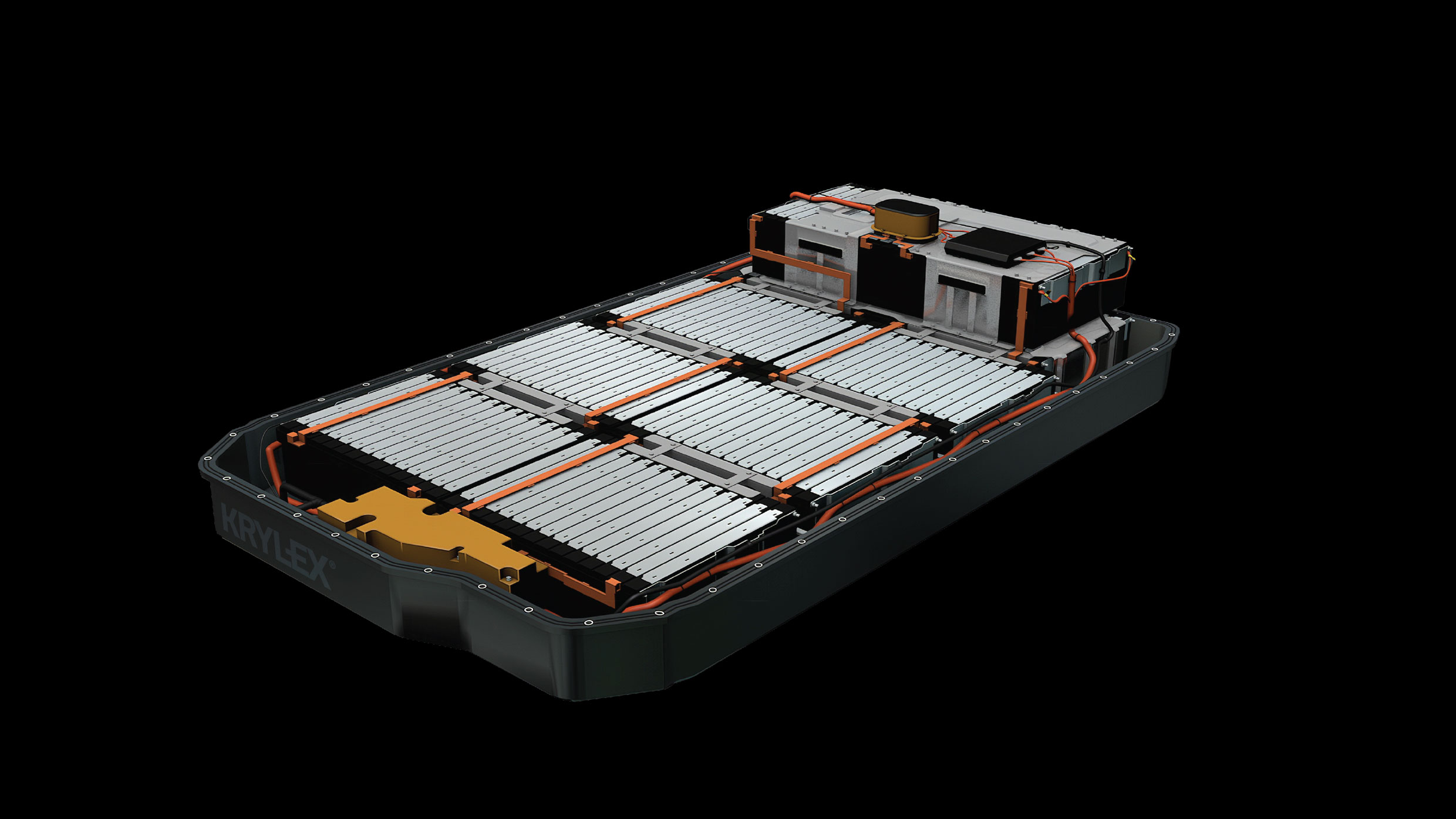

Battery Sealing Solutions

Hover over the targets to read more information

CURE-IN-PLACE GASKETING

CURE-IN-PLACE GASKETING

CURE-IN-PLACE GASKETING

KRYLEX® cure-in-place gaskets are UV curing materials that provide robust seals with minimal compression set repeated opening and closing for repair access.

FORM-IN-PLACE GASKETING

KRYLEX® form-in-place gaskets provide excellent thermal and chemical resistance while reducing manufacturing tolerances and replacing cut gasket inventories needed for cooling plates.

ANAEROBICS

Threadlockers and Thread Sealants applied to threaded fittings ensure reliability through vibration and thermal cycling – keeping nuts and bolts together and liquids contained in hoses and vessels.

VACUUM IMPREGNATION

ANASEAL® Vacuum Impregnation solutions use low viscosity polymeric resins to fill micro-porosity and voids in cast metal housing to form permanent seals.

SEALANTS/ENCAPSULANTS

Fast fixturing UV adhesives protect critical electronic components in the battery management system and provide secondary moisture cure for shadowed areas.

BATTERY CELL ASSEMBLY

Chemically resistant, ultra fast fixturing UV and PUR adhesives allow for large scale cell assembly for pouches or cylinders. See our next gerneration Battery Pouch Assembly adhesive;KU5144

BATTERY PACK ASSEMBLY

For fixturing cells to packs, adhesives make large scale assembly efficient while providing excellent mechanical properties and environmental resistance.

CURE-IN-PLACE GASKETING

KRYLEX® cure-in-place gaskets are UV curing materials that provide robust seals with minimal compression set repeated opening and closing for repair access.

FORM-IN-PLACE GASKETING

KRYLEX® form-in-place gaskets provide excellent thermal and chemical resistance while reducing manufacturing tolerances and replacing cut gasket inventories needed for cooling plates.

ANAEROBICS

Threadlockers and Thread Sealants applied to threaded fittings ensure reliability through vibration and thermal cycling – keeping nuts and bolts together and liquids contained in hoses and vessels.

VACUUM IMPREGNATION

ANASEAL® Vacuum Impregnation solutions use low viscosity polymeric resins to fill micro-porosity and voids in cast metal housing to form permanent seals.

SEALANTS/ENCAPSULANTS

Fast fixturing UV adhesives protect critical electronic components in the battery management system and provide secondary moisture cure for shadowed areas.

BATTERY CELL ASSEMBLY

Chemically resistant, ultra fast fixturing UV and PUR adhesives allow for large scale cell assembly for pouches or cylinders. See our next gerneration Battery Pouch Assembly adhesive;KU5144

BATTERY PACK ASSEMBLY

For fixturing cells to packs, adhesives make large scale assembly efficient while providing excellent mechanical properties and environmental resistance.

ADAS: (Advance Driver Assistant Systems)

Advance Driver Assistant Systems have proliferated to almost all new vehicle models on the market today. These systems critically enhance the safety of drivers and passengers by monitoring road conditions, warning drivers of hazards and even intervening to keep people safe. While these systems are composed of delicate electronic componentry, they are exposed to harsh weather conditions found around the world throughout a range of seasons. KRYLEX® adhesives and sealants provide reliable bonds that are impact and shock resistant and protect from the environment and exposure to chemicals all while allowing manufacturers to decrease assembly weight and increase production throughput.

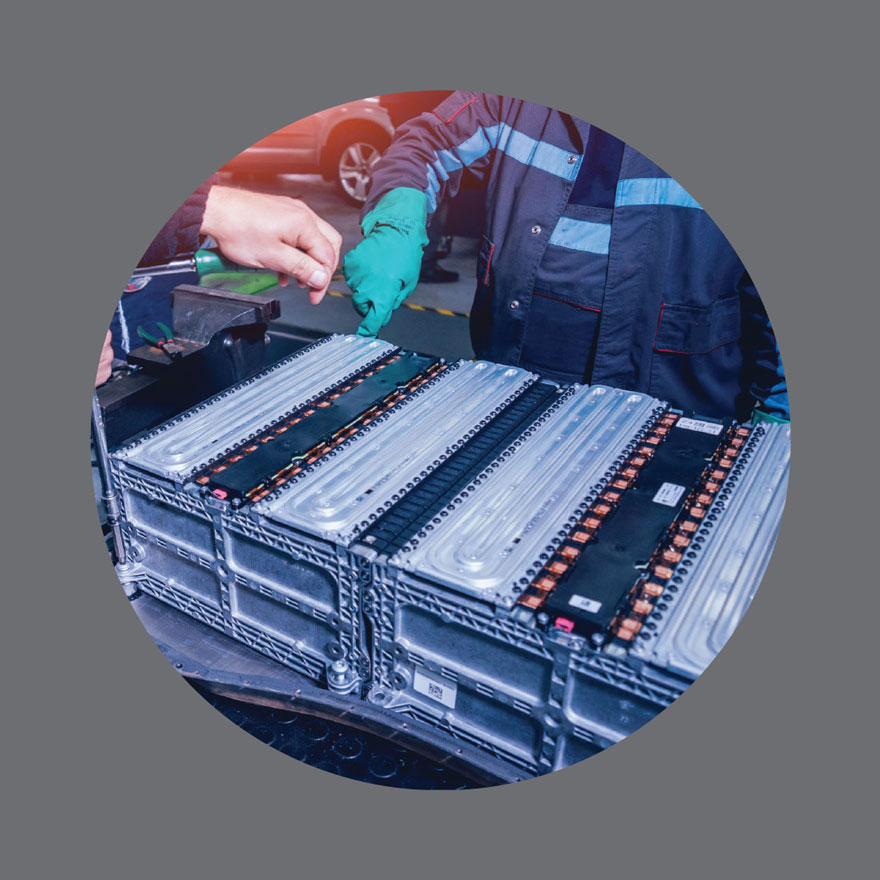

Batteries:

Battery Systems for electric vehicles are complex assemblies requiring several adhesives and sealants to ensure proper performance and long lifecycles. Chemence® has been delivering market leading lithium-ion battery pouch sealing materials for years for the electronics industry. KRYLEX® gasketing materials provide ingress protection from the environment, minimize noise and vibration and increase efficiency and decrease weight of the pack. Chemence® also offers several solutions for structural assembly of the battery packs, encapsulation of the battery management systems and even threadlockers and thread sealants for proper assembly of nuts and bolts.

Displays:

The combination of entertainment and information delivery is a growing desire among consumers when considering new vehicles. In addition to traditional radios and vehicle performance gauges automotive OEMs are increasingly incorporating voice command systems, navigation capabilities, mobile device connectivity and safety systems into their displays. The ability to deliver information reliably with high quality is critical and KRYLEX® adhesives play an integral role in the assembly of displays used to deliver this data.