Adhesive Selection for Wireless Charging Technology

Wireless Charging is become an increasing important and common method for charging electronic devices across a wide variety of industrial segments. These segments include Aerospace, Defence, Healthcare, Industrial, Automotive and Consumer Electronics.

The advantages of a wireless approach compared to more standard charging approach via an attached cable are numerous. One of the obvious advantages to wireless charging as a technology is the simple convenience for the user but there are other more tangible advantages, like the removal of large, bulky power cables. Or as is the case for some health care applications, wireless charging helps reduce the transfer of bacteria and other impurities in sterile environments. In industrial applications the adoption of wireless charging technologies is also resulting in a safer working environment because of reduced fire risk associated with stray sparks that can occur during connection and disconnection of industrial power cables. In addition, wireless charging also offers further safety advantages as it enables waterproof, airtight sealed surfaces as opposed to the less contained traditional plug and socket.

Wireless Charging Technologies

There are a variety of wireless charging technologies that have been developed into commercially applied technologies used in industry today. The three most common wireless charging technologies are:

- Inductive Charging - Using electromagnetic induction, the device can be placed near the charging station without the need to align precisely.

- Resonant Inductive Coupling – Coupling becomes stronger when the secondary side of the loosely coupled coil resonates.

- Radio Frequency (RF) -Uncoupled charging in which an antenna in an electronic device can pick-up low-level radio frequency waves from an external source and convert the wave energy to direct current (DC) voltage.

Wireless Charging in Consumer Electronic Applications

The market size for wireless charging was estimated be between 10 – 12 billion USD in 2019 and was projected to grow at 14.5 CAGR through 2029. By far the largest market share for wireless charging is consumer electronics (~45%), mostly driven by product innovations with mobile devices (such as smartphones and tablets) as well as, the rapid growth in wearable electronic devices. These consumer electronic devices are ‘low power’ devices e.g., <100 Watts, and as a result the dominant wireless technology used is inductive charging. In addition to being ideal for low power device charging applications inductive charging does offer other significant benefits for consumer electronic device applications:

- Protected connections that are free from corrosion resulting in reduced risk of shorts or insulation failures.

- Intermittent recharging, with frequent reconnections, without wearing connectors.

- Increased convenience and improved aesthetics.

- Increased durability.

- Automatic, no human interaction required.

Some of the negative aspects associated with inductive charging compared with other charging methods are:

- Slower charging, approximately 15% slower than plug to socket.

- Increased manufacturing complexity meaning increased cost.

- Increased heat that can result in reduced battery life.

- Inconvenience of being unable to use while charging.

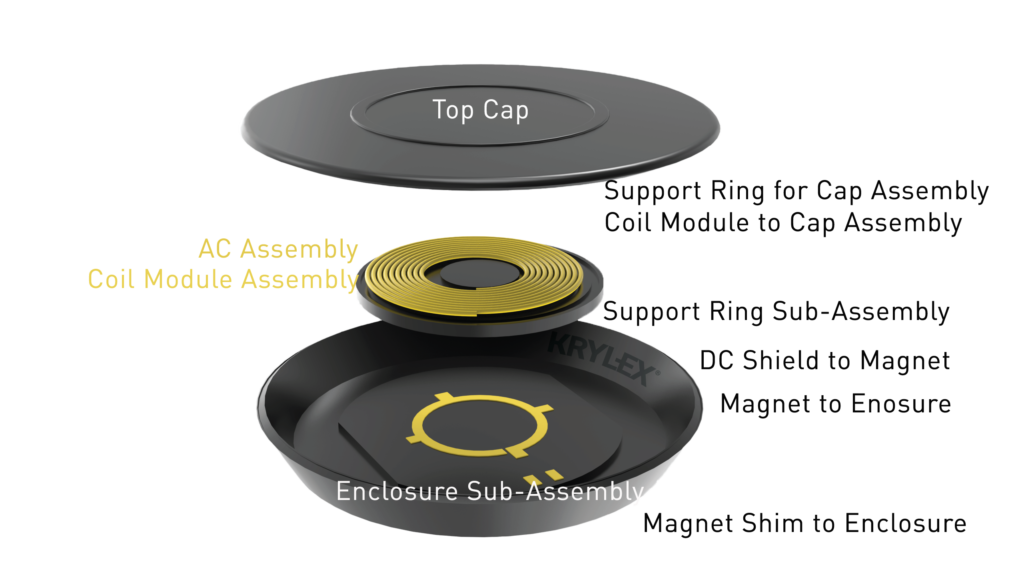

Typical Inductive Charging Wireless Charger Construction.

The wireless chargers used in the consumer electronics industry today vary in design, shape and size however typically have relatively consistent constituent parts. These applications typically use adhesives as the preferred method of joining technology and are usually performed as part of the wireless charger enclosure construction or during the FATP process.

Enclosure Construction:

The typical wireless charger will incorporate numerous magnets bonded into the device enclosure using an adhesive. The magnets are usually situated around the periphery of the device enclosure and need to be bonded to both a DC shield and magnet shim. The different bonding surfaces will often require the selection of multiple adhesive products to get the best reliability and performance. Typically, it is common for Hot Melt PUR adhesives to be the best adhesive chemistry choice for bonding these components into the enclosure casing. Often the adhesives will have to provide good adhesive characteristics when boing the dissimilar substrates used e.g., Ferrite to Polycarbonate (PC) or Ferrite to Polyimide (PI). Depending on the product selected the adhesive needs to provide the balanced adhesion to both bonding surfaces but also be compatible with the inherent sensitivity of the substrate materials. Magnet performance can be significantly impacted if exposed to elevated temperatures while often the plastics can be degraded, and aesthetic appearance impacted by elevated temperatures. As such heat cure adhesive solutions are not practical. In addition, using 2-part (2k) Epoxy and Acrylate chemistries would not provide sufficient impact performance that is required with this kind of electronic device accessory. The appropriate Polyurethane Hot Melt adhesives offers customers a RT process that protects sensitive substrates but also offers a balanced adhesion between plastics and metal while providing industry leading impact performance to ensure product reliability.

Final Assembly, Test and Pack (FATP):

After initial enclosure assembly and bonding, the next part of wireless charger assembly will normally proceed to the FATP line. FATP is the process of assembling, often by hand, a product from different parts. This process is often done in an assembly line where at each station the operator has only one function i.e., adding one piece, gluing one component to another, etc. A significant part of the FATP wireless charger assembly process is the incorporation of the coil assembly, ring support sub assembly and AC sub-assembly. Again, it is often required to bond metals such as ferrite to high surface energy (HSE) plastics e.g., Polycarbonate (PC). PUR Hot Melts continue to be the best choice of product class for this part of wireless charger construction process. The choice of product will be dictated by the substrates involved but also its relative location to the wireless charger coil. PURs used to bond near the coil need to offer both high and low temperature resistance, because heat will be generated when charging is in process, but the assembly will cool when the charger is not in use. The adhesive needs to be able tolerate these heating and cooling cycles throughout the lifetime of the device, which could mean hundreds or thousands of cycles.

KRYLEX® KH9000 Series Polyurethane Hot Melts for Wireless Charger Assembly:

KRYLEX® KH9000 Series Products are novel Polyurethane (PUR) Reactive Hot Melt Adhesives that deliver a variety of performance benefits in the assembly of Consumer Electronic mobile Devices, and device accessories e.g., Wireless Charger. KH9000 series offer outstanding adhesive performance whilst also offering customers increased sustainability and end of life re-workability.

KRYLEX® KH9012 Polyurethane Reactive Hot Melt:

KRYLEX® KH9012 is a highly engineered Reactive Hot Melt PUR adhesive designed for high performance structural bonding of electronic components and enclosures. KH9012 has excellent adhesion to metal and plastics along with a high storage modulus for increased reliability. KH9012 material properties make it an ideal choice for the assembly or wireless charger assemblies, and it designed to be able to be used for number of different bonding applications in the construction of the device e.g., Coil module assembly, magnet bonding, device enclosure, etc. This provides manufacturers both high performance bonding and reduced supply chain complexity (fewer adhesives used in construction).

KRYLEX® KH9035 offers the following advantages over other similar PUR Product formulations

- Best in class jet dispense performance.

- High and rapid green strength development – reduced clamping times in applications.

- Excellent adhesion to common plastics and metals.

- Bubble free bond lines, after adhesive cure.

- Excellent elongation for improved impact reliability performance.

- Elevated product modulus for improved drop performance

- Excellent Moisture barrier properties.

Summary:

KRYLEX® KH9000 Series PURs offer unique benefits to customers in the assembly of consumer electronic devices and accessories. In the case of wireless charger assembly KH9012 provides high levels of adhesion and device reliability when bonding metals to plastics.

For more information, please contact Paul Gleeson at pgleeson@chemence.com or your local KRYLEX representative

December 16, 2022

Krylex