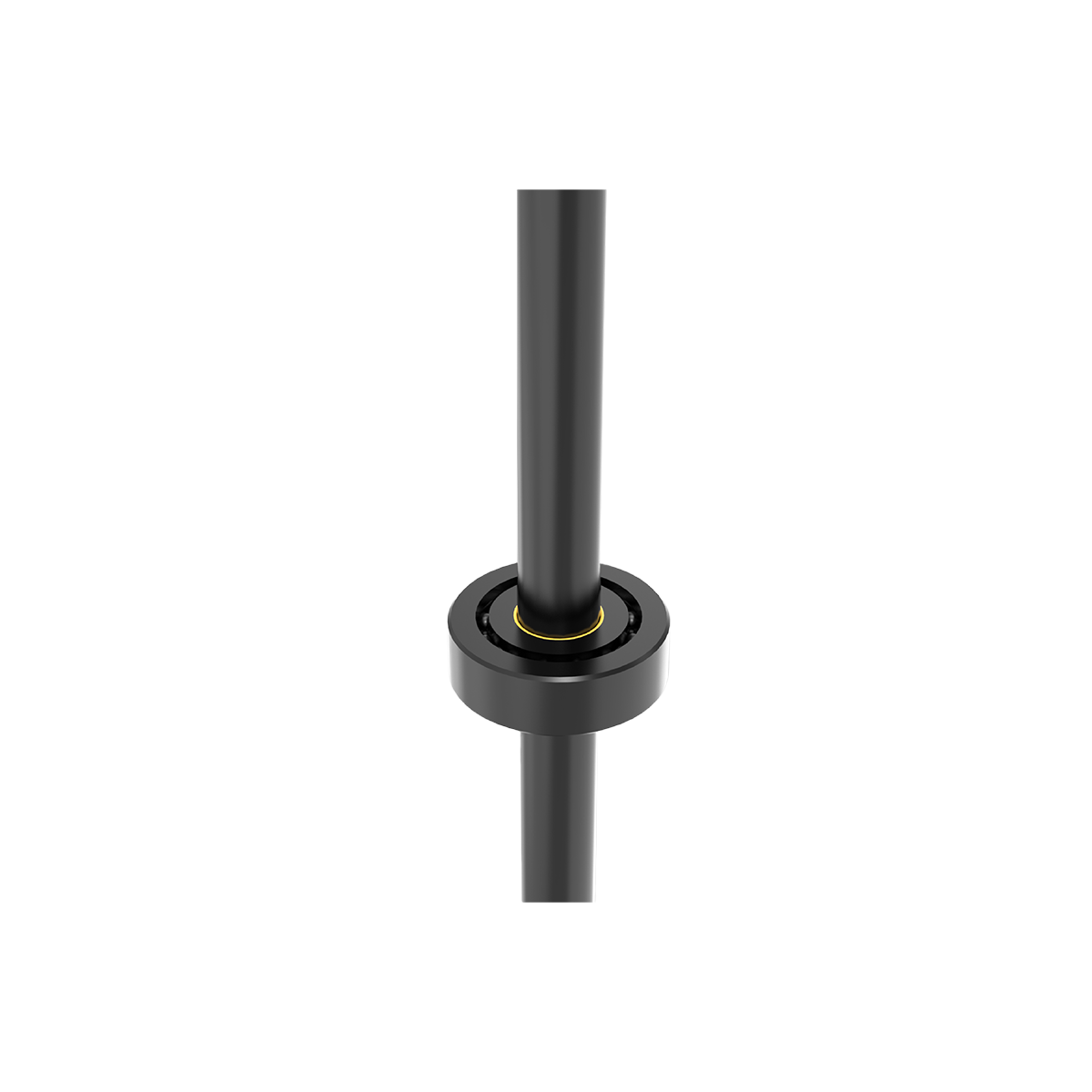

Sealing

Preventing Ingress Of Any Substance

The term sealant is used when the primary concern is keeping harmful matter out. In industries such as Consumer Electronics, sealants are commonly specified. Sensitive and complex electronic assemblies such as Printed Circuit Boards (PCBs) will lose functionality if exposed to unfavorable conditions.

These conditions could include the penetration or ingress of dust, debris, or any particle that if became lodged on a PCB could interfere with electrical proper-ties of the device. Additionally, gases and liquids are usually of greater concern. Liquids such as water or even common chemicals used every day by consumers such as sunscreen, insect repellant, perfume and cosmetics have the potential to penetrate adhesive joints and cause damage. Water vapor can penetrate certain materials in solid form and condense onto the very components the adhesive joint was designed to protect.

Keeping Out All Environmental Elements

KRYLEX® range of adhesive technologies combine good adhesion with excellent sealing properties. Of course, before specifying it is important to understand what substance a design is required to seal against and the length of possible exposure. KRYLEX® has a range of sealant technologies shown below.

Their features include:

- Excellent chemical resistance

- Low moisture vapor transmission rate (MVTR)

- Low coefficient of thermal expansion (CTE)

- Good adhesion to common plastics and metals

- Flexible/ High Elongation

- Excellent peel and impact strength