Encapsulation

Localized Sealant used to protect sensitive components

Electronic components require protection against moisture, dust, debris, or everyday chemicals. Although most electronic devices incorporate a protective housing that offers a certain level of protection, this is often not sufficient to ensure excellent reliability. Apart from the ingress of harmful particles and liquids, electronic devices are subject to be dropped and therefore must have additional methods to absorb impact resistance. There are many ways to utilize an adhesive technology add an extra layer of protection such as conformal coatings or potting.

Encapsulation is achieved when the adhesive is applied directly onto a component at a certain thickness. This coating or layer of adhesive when cured will provide mechanical protection against impact along with moisture and chemical resistance. Differential thermal expansion must also be accounted for in specification. Encapsulants with a low Coefficient of Thermal Expansion (CTE) must be chosen to prevent warpage and damage to wire bonds.

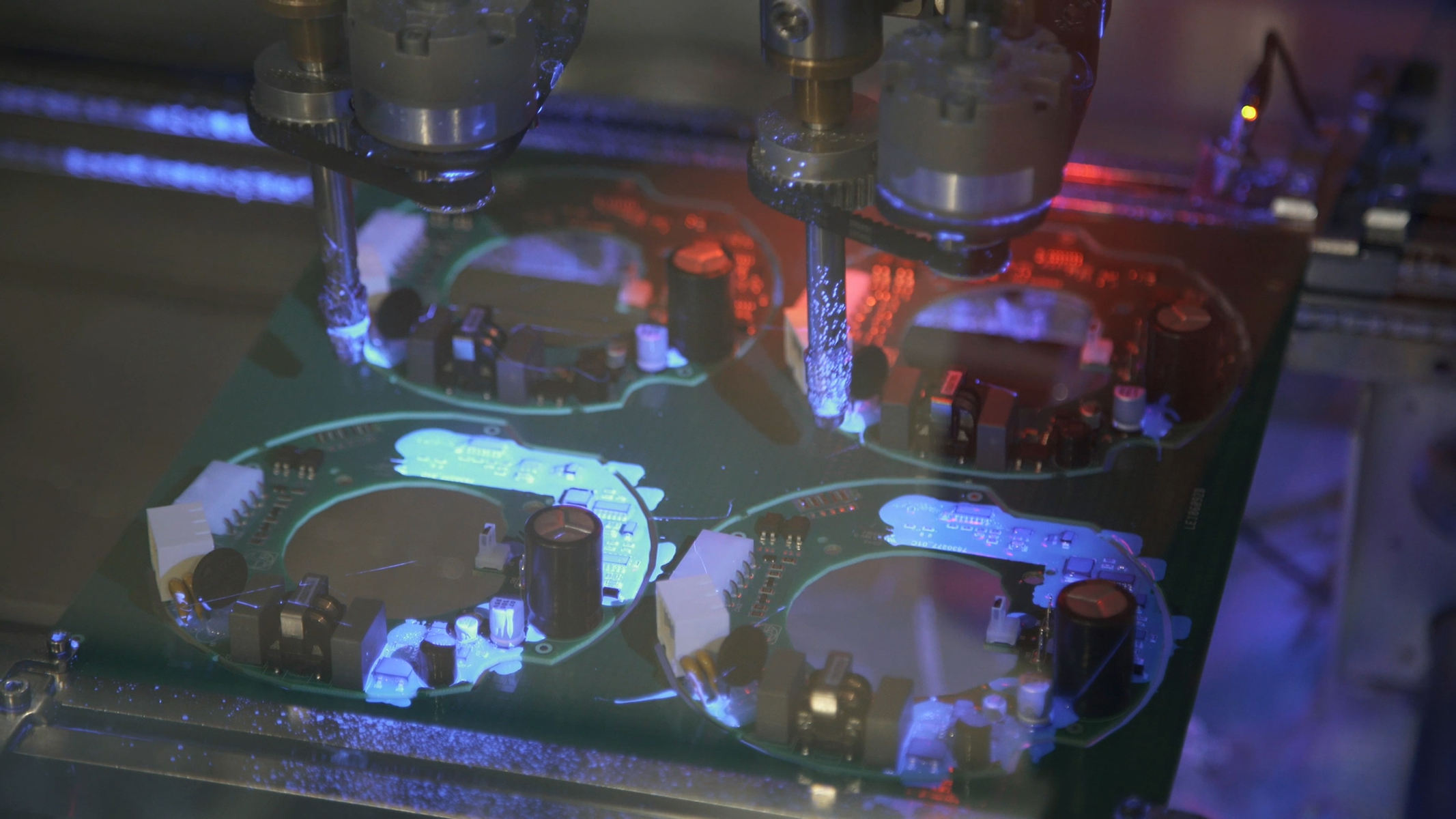

Potting & Encapsulating protect PCBs

KRYLEX® range of UV curable encapsulants offer outstanding environmental and mechanical performance. Their features include:

- Excellent Adhesion to difficult to bond, temperature sensitive plastic and metal substrates.

- Rapid UV Cure to maximize production equipment efficiencies, <3 secs.

- Low outgassing

- Solvent free

- Exceptional depth UV penetration

- Tailored rheology for easy dispense

- Capable of both needle and jet dispensing

- High Reliability