KH9012 PUR Hot Melt

Structural Bonding Adhesive

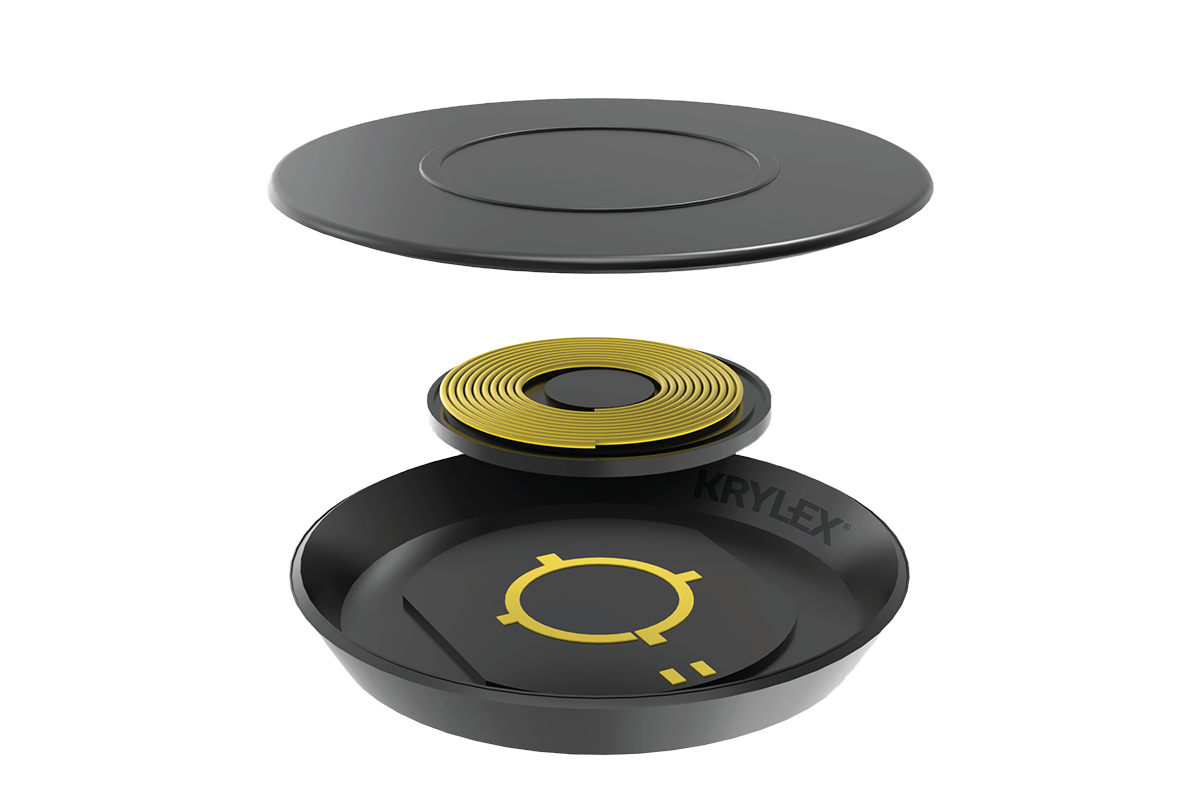

KH9012 is a Reactive Hot Melt PUR adhesive designed for high performance structural bonding of electronic components and enclosures.

As a group, KH9000 Series products are designed to deliver next generation PUR product performance across a wide variety of applications. Key performance properties include:

- Chemical resistant

- Bubble-free curing

- Excellent adhesion to both polar, non-polar and oily substrates

- KH9001 and KH9005 are reworkable grades.

- Dispensable PSA: Both KH9001 and KH9005 offer long tack times (20 minutes)

- Excellent reliability

- 10993-5 bio-compatible

- Highly sustainable -~ 50% bio-content

- Ultra-high moisture barrier properties –Low MVTR -0.327 g/hr-m2

Applications: Wireless Charger bonding

KH9012 At A Glance

Low Dielectric Constant, Low MVTR, Excellent Chemical Resistance, High Green Strength

>3mins

OPEN TIME

900%

ELOGATION AT BREAK

0.327

g/hr-m2 MVTR

2,400

VISCOSITY CPS

BUBBLE-FREE

APPEARANCE / BUBBLE

*Fixture time is defined as the time to develop a shear strength of 0.1 N/mm2 (14.5psi) between two glass slides; Black light, 365nm, 6mW/cm2 for 1 second. Depth of cure chart presents data using Medium Pressure Mercury Arc Lamp at 100mW/cm2

CHEMICAL RESISTANT

KH9012 shows no surface blemishes and minimal change in tensile properties after chemical exposure

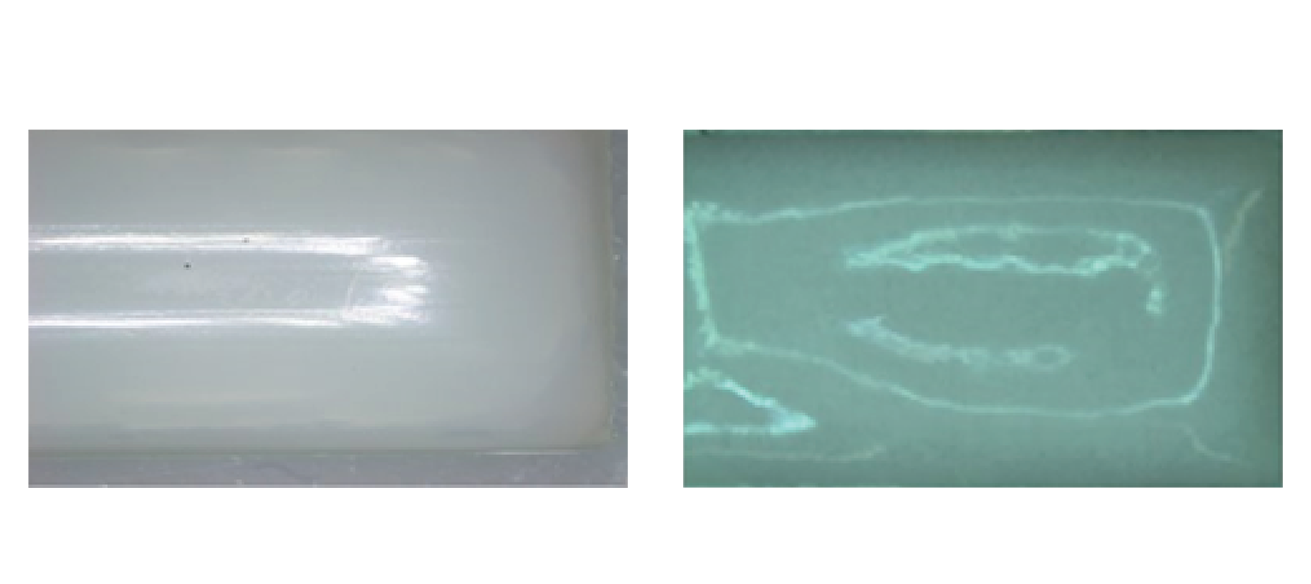

LOW OFF-GASSING

KH9012 shows very low Bubble formation post cure.

BIOCOMPATIBLE

KH9012 has over 50% Bio-content and is ISO-10993 certified

KRYLEX® KH9012 advantages vs competition include:

- Best in class jet dispense performance.

- High and rapid green strength development.

- Excellent adhesion to most plastics and metals.

- Bubble free bond lines, after adhesive cure.

- Improved impact reliability performance.

- Improved drop performance

- Excellent moisture barrier properties.