KU5146 UV Curable IR Bonding Adhesive

KU5100 series focus on delivery high performance solutions for Compact Camera Modules. Depending on the specific bonding application, each adhesive will have very different performance requirements.

The KRYLEX® Camera Module Assembly Adhesive range ensures:

- High manufacturing throughput achieved through on-demand curing UV technology

- Excellent optical performance and low-shrinkage

- RoHS-compliant, isocyanate free and solvent free

- Excellent dispensability

- Excellent mechanical properties leading to outstanding reliability and functionality

Specific to optical bonding, KU5146 is formulated to be used in IR glass bonding applications:

- Refractive index of ~1.56

- Adhesion to glass

- Optically clear (non-yellowing) formulation

KU5146 At A Glance

High Refractive Index, Maintains Optical Clarity After Aging, Tack Free

310

VISCOSITY (cP)

1.56

REFRACTIVE INDEX

0.9%

WATER ABSORPTION 2hrs @ 100◦

1100MPa

TENSILE MODULUS

<3%

SHRINKAGE

CURE DEPTH

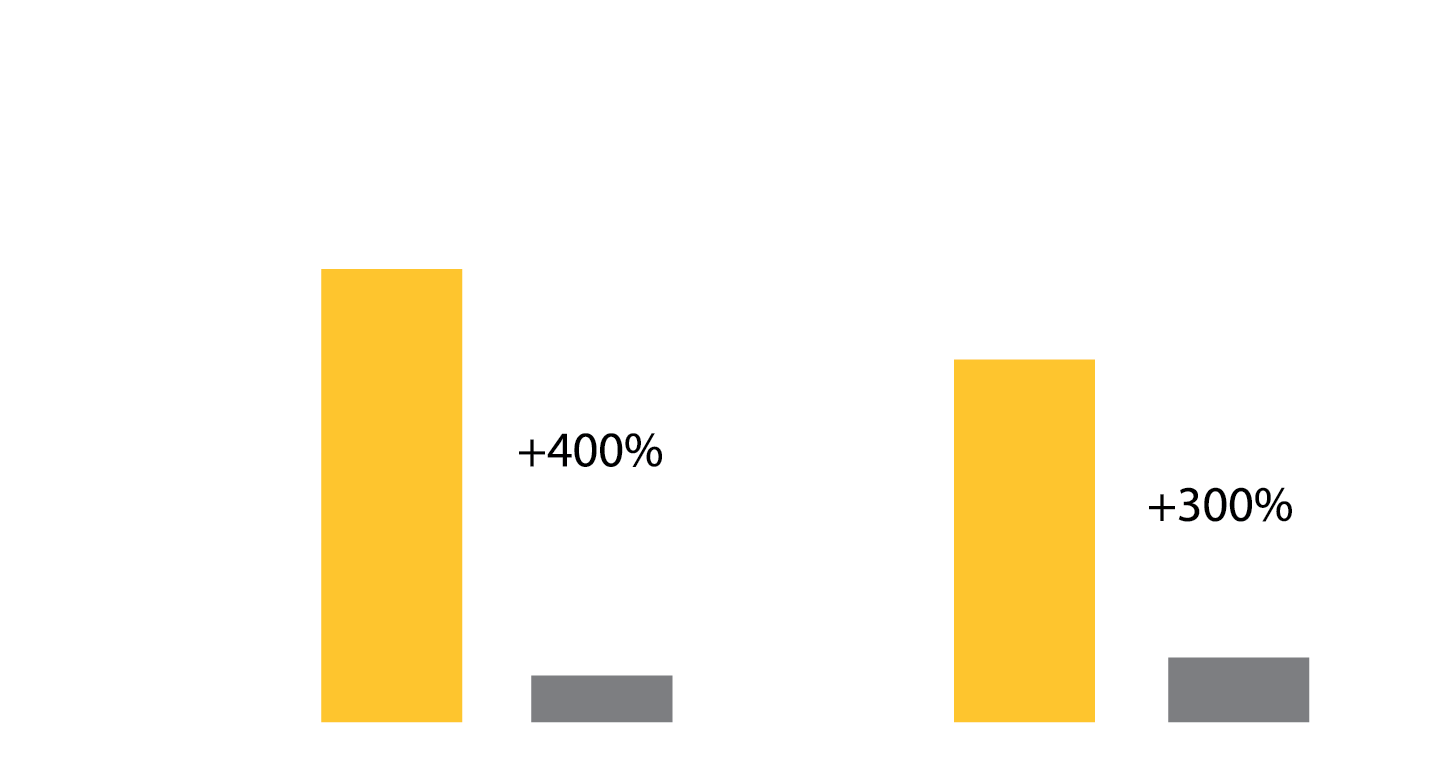

KU5146 has phenomenal cure depth of up to 25mm. 10x better than competition.

CURE SPEED

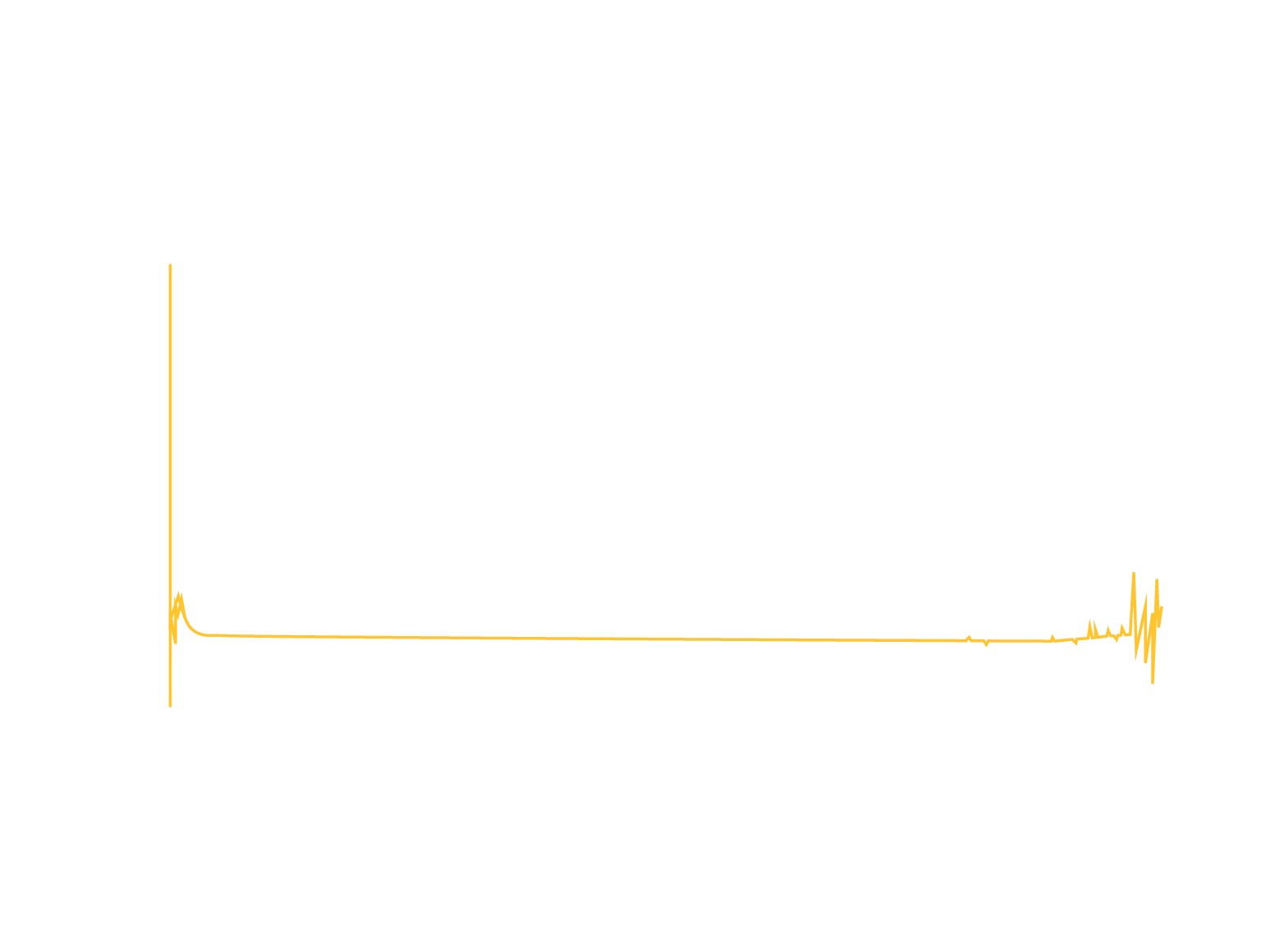

KU5146 has fast tack free cure in under 3 second with UV/LED exposure.

OPTICALLY CLEAR

KU5146 has excellent optical clarity and cures transparent.

CURE DEPTH

KU5146 has phenomenal cure depth of up to 25mm. 10x better than competition.

CURE SPEED

KU5146 has fast tack free cure in under 3 second with UV/LED exposure.

OPTICALLY CLEAR

KU5146 has excellent optical clarity and cures transparent.

KRYLEX® KU5146 Benefits:

- Lens Bonding: KU5146 UV curable acrylate adhesive is optically clear with a high refractive index to meet strict optical requirements. It will not yellow over time.

- Low shrinkage and abrasion resistant.

- Excellent adhesion to glass.

- Cure is not inhibited by Oxygen

- The tack-free cure surface ensures optical assemblies are not easily contaminated.

- Refractive index of ~1.56