Greener and Safer Adhesive Solutions

KRYLEX® More Environmentally Friendly & High Bio-content Adhesives:

Consumer electronic device manufacturing companies constantly strive to deliver devices that enhance people’s lives through improved form and function. In addition to an enhanced experience for the user, increasingly consumer electronic device manufacturers are also looking to deliver their products to the market in a way that meets their commitments in respect of corporate responsibility, most notably lower carbon emissions and a safer device use experience for the consumer.

It is becoming increasingly important for large global corporations to be seen to be delivering their products to market in a responsible and sustainable way. Notably, Apple Inc has committed to becoming carbon neutral across its entire business, manufacturing supply chain, and product life cycle by 2030. The company is already carbon neutral today for its global corporate operations, and this new commitment means that by 2030, every Apple device sold will have net zero climate impact.

Apple CEO Tim Cook was recently quoted as saying “Businesses have a profound opportunity to help build a more sustainable future, one born of our common concern for the planet we share’’. Cook further stated “The innovations powering our environmental journey are not only good for the planet — they’ve helped us make our products more energy efficient and bring new sources of clean energy online around the world. Climate action can be the foundation for a new era of innovative potential, job creation, and durable economic growth. With our commitment to carbon neutrality, we hope to be a ripple in the pond that creates a much larger change.”

These corporate commitments to significantly lower carbon emissions have clear implications for material suppliers across the consumer electronic device supply chain. One key focus for Electronics OEMs in respect of adhesives is to increase the use of adhesives with increased ‘Bio-content’. Specifically, the focus is to increase the use of bio-based solutions used in the device enclosure bonding and sealing. Bio-based polymers are defined as materials for which at least some portion of a product consists of material produced from renewable raw materials (e.g., Soybean, corn). Bio-based resin solutions have some clear and obvious advantages over petroleum synthetic alternatives. Bio-based resins are inherently more sustainable than fully synthetic petroleum-derived resins commonly used in adhesive formulations. Using bio-renewable or waste feedstock helps to reduce the carbon footprint by eliminating the need for petroleum-based synthesis. Bio-based resins are also non-toxic (or less toxic than synthetic equivalents). Furthermore, petroleum-based resins are also subject to shortages in oil and significant price fluctuations based on the market price of oil. Whilst the case for bio-based adhesives is clear, there are challenges for adhesive suppliers when using bio-based solutions. These challenges need to be understood and mitigated. The primary downside to bio-based products is that they typically have lower performance levels compared with fully synthetic resins (e.g., less efficient adhesives). Large consumer device companies typically cannot compromise on the performance of the adhesive because they cannot accept a reduction in device robustness/ reliability.

KRYLEX® Bio-based Adhesive Solutions:

To meet customer requirements around sustainability KRYLEX material chemists are routinely identifying and using high-performance renewable resin constituents and components, for electronic device enclosure bonding applications. One such example where bio-based constituents have been successfully used is in the formulation of Reactive Hot Melt Polyurethanes, specifically KRYLEX® KH9000 series products.

KRYLEX® KH9000 Series Products are novel Polyurethane Reactive Hot Melt (PUR) adhesives that deliver a variety of performance benefits in the assembly of Consumer Electronic mobile Devices, wearable devices (both consumer and medical), and device accessories. KH9000 Series offers the customer a range of high-performance benefits ranging from best-in-class device enclosure sealing, antenna bonding, or encapsulation of die and components in wearable applications, all while offering customers increased sustainability using high bio content raw materials. KH9000 Series contain high levels of plant-based raw materials of up to 50%. For all these reasons KH9000 series is a highly sustainable product family for customers building electronic devices.

KRYLEX® KH9000 Series Performance Benefits:

KRYLEX® KH9000 series products have been formulated with unique properties to deliver next-level performance in a variety of adhesive application spaces. KRYLEX® KH9000 series has exceptional moisture barrier properties once cured, as a function of a very low moisture vapor transition rate (MVTR), and have found widespread use in the sealing of electronic device enclosures where moisture penetration cannot be tolerated. The product series also meets skin sensitivity standard ISO 10993-5; a critical requirement when being used at the extremity of electronic devices which will see contact with the human body and means the product can be used for consumer and medical electronic devices.

KRYLEX® KH9000 Series PUR adhesives offer customers both a sustainable choice and a product platform of unique performance characteristics in the assembly of electronic devices in a rapidly changing world:

- One component.

- High Green strength in minutes.

- A variety of adhesive “open times” or time before the final bonding of substrates.

- Cure at ambient Temperature (moisture cure).

- High Bio-content adhesive formulas.

- Highly sustainable value proposition.

- Best-in-class sealing properties.

- Optimized Dielectric properties for antenna bonding.

- Excellent adhesion to plastics and metals.

- High Elongation.

- High impact strength (reliability).

- Reworkable

- ISO 10993-5 compatible (skin sensitivity).

- RoHS Compliant

More Biocompatible and Safer Adhesives:

There have been a number of high-profile class action lawsuits resulting from adhesives irritating the skin of the user, most notably when using electronic devices worn or used in close proximity to the body. Adhesives, in general, have the potential to cause skin irritation often referred to as ‘contact dermatitis. The most common adhesives associated with skin irritation and sensitivity are acrylates, including methacrylates, and epoxy diacrylates. The use of these types of resin technologies is widespread in electronic adhesive formulations and poses a significant problem as electronic devices are ever more frequently in contact with the skin. The specific risk is associated with trace formulation constituents that can leach out from the reacted adhesive. Often moisture from human sweat can act as the vehicle to help leach and transport the constituents into contact with the skin and cause irritation.

In addition to the issues with skin irritation, some adhesives can have pungent odors that are often uncomfortable to work around and, in some cases, cause respiratory issues and headaches. Acrylic-based adhesives often contain strong-smelling Isobornyl Acrylate (IBOA) and over time the use of IBOA is becoming less desirable because of these reasons. For these reasons, it is often desirable and sometimes necessary to create adhesives that do not have these common safety use issues.

KRYLEX® UV Curable, ‘Low-Extractable’ Adhesives for Mobile/ Wearable Device Assembly Applications:

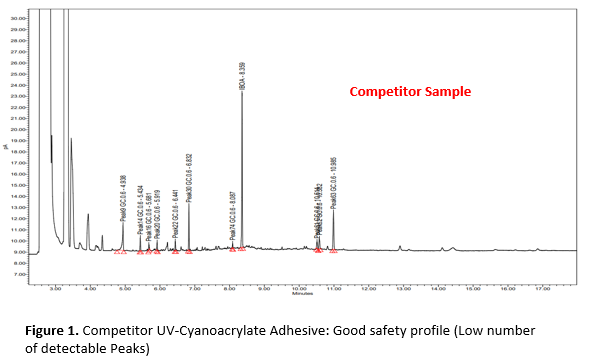

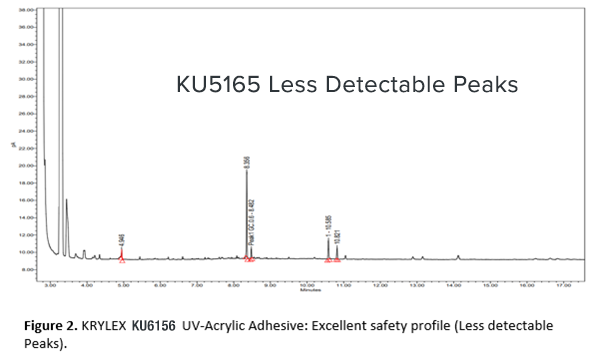

KRYLEX® UV curable adhesives with low ionic extractable content are designed for bonding applications that will be used in close proximity to the human skin. After cure, they have very low detectable chemical peaks when analyzed by HPLC and as such have an excellent safety profile making them ideal for wearable electronic and mobile device assembly, Figures 1 & 2:

The adhesives are designed to be free of IBOA, Phenol, and DMA and formulated to be RoHS and REACH-compliant, as well as irritant-free. The adhesives are designed to have fast UV cure kinetics and, depending on the formulation, have targeted performance on both high and low-surface energy substrates.

KRYLEX® material scientists have created high-performance adhesives that enable customers to achieve desired levels of performance while offering the adhesives in formats that are both highly renewable and safer to use. KRYLEX® is uniquely positioned at the intersection of medical devices and general industrial. Chemence has a deep understanding of low-extractable and biocompatible adhesives and is the leading manufacturer of adhesives, sealants, and resins for automotive, electronics, consumer, medical, and industrial applications, and has been setting new standards of performance for all bonding and sealing requirements. Being the leading industrial adhesives manufacturer with an eye for performance, we are committed to delivering quality bonding and sealing solutions.

For more information or to arrange product sampling contact Paul Gleeson at pgleeson@chemence.com.

October 26, 2022

Krylex