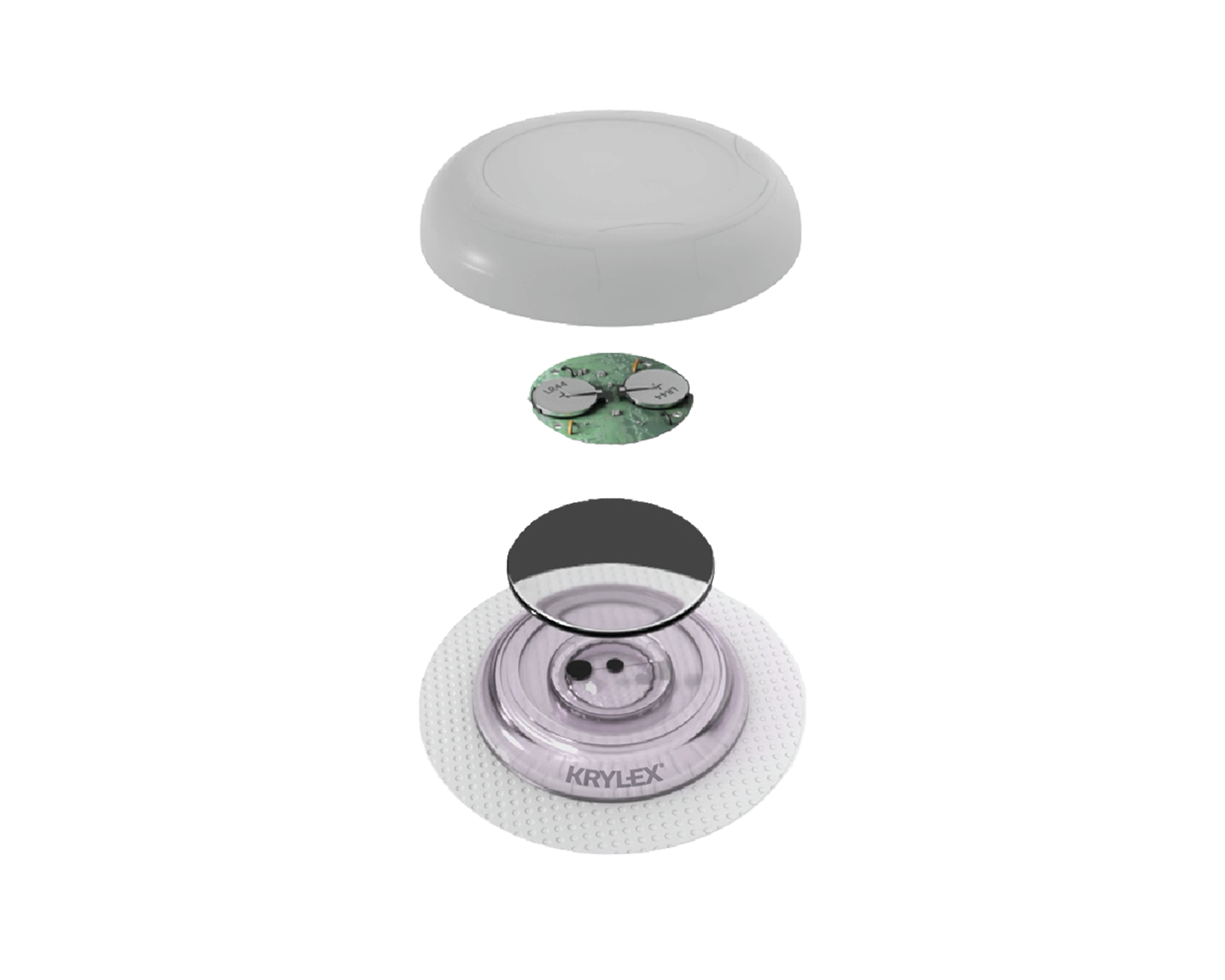

KU5165 Low Extractible UV Adhesive for CGM Assembly

KRYLEX® KU5160 Series products are formulated for applications where the assembled device will spend extended periods on or close to the human body and is required to meet industry biocompatibility standards e.g. 10993-5. The benefits of the products include:

- Low extractable (CH3OH and Saline)

- IBOA and DMA free

- Low irritant and excellent safety profile

- Fluorescent

- Cures quickly upon exposure to UV/LED

- Good adhesion to plastic/polyimide

- Good water resistance

- Optimized viscosity profile for dispensing

- Offer stable adhesive performance in different reliability test conditions

Most importantly, KU5165 has virtually no detectable extractables in GC-MS testing.

Applications: Continuous Glucose Monitors, Insulin Pumps, VR Head Sets and Other Wearable Technology.

May 2024

Samantha Leap presented this paper at RadTech 2024 Conference and won Best Paper Award for the work.

Abstract

Continuous glucose monitors (CGMs) are quickly gaining popularity with an estimated 2 million patients due to their ease of use. This two-week wear device allows patients to automatically check glucose levels via their phone without the need to prick their fingers multiple times a day. While this technology has been revolutionary for diabetes patients, the new device doesn’t come without issue. Skin irritation issues have been reported by patients wearing such devices caused from the UV adhesive used within the components of these devices. In fact, this issue is not seen in just CGM devices, but rather encompasses a much broader range of UV adhesives utilized in a variety of wearable devices. These wearable devices can be smart watches, headphones, GCMs, or even electronic cigarettes.

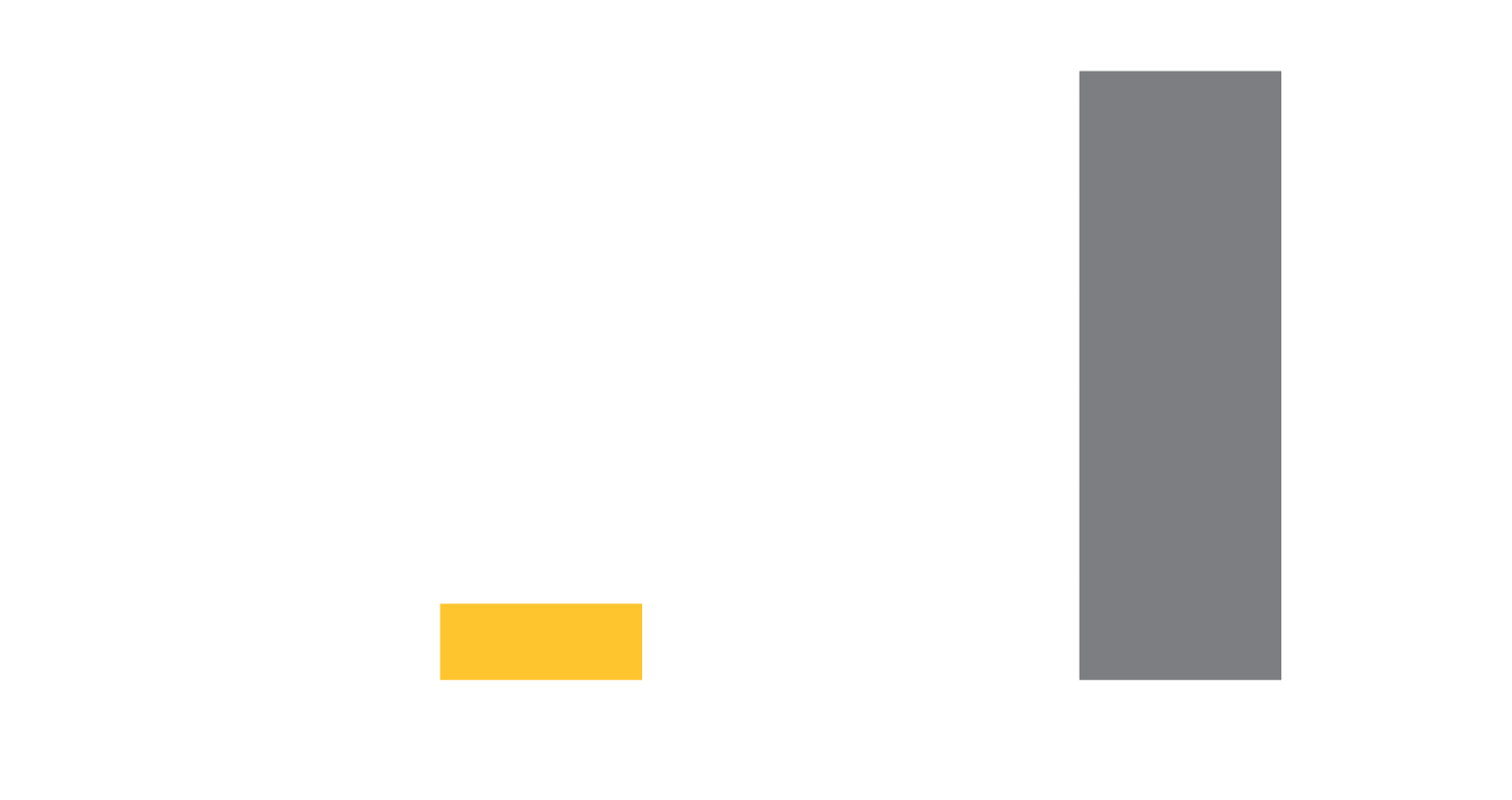

Developing safer, more biocompatible, less hazardous UV adhesives will immensely help users of all wearable devices. This research dives into the development of safer, less hazardous UV adhesives by utilizing safer monomers and oligomers when formulating and ultimately ensuring these adhesives have less extractable and leachable unreacted materials. Testing via HPLC and GC-MS yielded a 93% reduction in extractable materials when compared to a low viscosity, grade 2 ISO-10993-5 cytotoxicity certified, UV curable formulation utilized in needing bonding applications. This discussion comprises formulating strategies of both traditional acrylate adhesives and the benefits of adding in a thiol-ene as a reactive diluent. The addition of a thiol:ene as a reactive diluent yielded up to a 60% reduction in extractables by means of HPLC and GCMS when compared to its pure acrylate counterpart. Adhesive requirements and their appropriate test methods, biocompatibility, and the future uses of low extractable UV adhesives will also be discussed at length.

Download full paper CLICK HERE.

KU5165 At A Glance

Low Extractable Content, ISO-10993-5, IBOA/DMA Free

65%

ELONGATION

35D

SHORE HARDNESS

2,500CPs

VISCOSITY

5.2MPa

SHEAR STRENGTH 1” PC – PC OLS MPa

2.3MPa

SHEAR STRENGTH 1” PC – KAPTON OLS MPa

KU5165 Ultra Low Detectable Levels of Extractable Material (ppm)

*Test Mehtod: 1g of the adhesive is weighed on a clean glass slide. It is then sandwiched with another piece of clean glass slide and the pair is then cured under 405 LED for a total UV dosage of 50J. Sample is let to stand at RT for 30 minutes and then dipped in 25 mL HPLC grade Methanol. Samples were immersed in Methanol at RT for 24 hours. Extracted media submitted to GC-MS and HPLC analysis. Based on GC and HPLC run on different lots, PI is not detected in any of the samples.

Grade 0 ISO 10993-5 Score

KU5165 has a score of zero in ISO10993-5 cytotoxicity testing. The product showed no reactivity in culture testing. Acceptable scores in other products are as high as two.

Biocompatible / Irritant Free

KU5165 formulation is Isobornyl acrylate (IBOA) and Dimethylacrylamide (DMA or DMAc) free.

BONDS TO DIFFICULT SUBSTRATES

KU5165 offers good adhesion to both Polycarbonate (plastics) and Kapton (polyimide). It also has stable adhesive performance in different reliability test conditions.

KRYLEX® KU5165 Benefits:

KU5165 is fast UV Cure adhesives with an excellent usage safety profile with very low extractable trace ionics after cure. The benefits of this product include:

- Low extractable/low irritant/no skin sensitizer

- fluorescent UV adhesive

- UV cure at 365-405nm LED, ~5J

- Good adhesion to Plastics/Polyimide/li>

- Good water resistance

- High thixotropy for optimum dispensability

- Superior aging performance in thermocycling, water cycling testing.