Industrial

High-Performance Adhesives

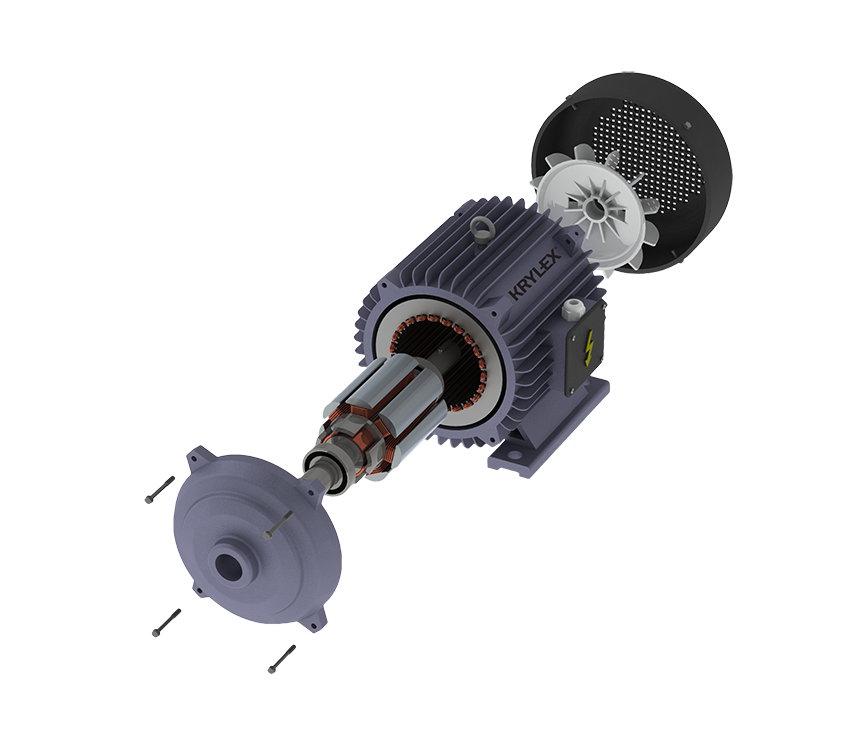

Industrial manufacturers around the world rely on KRYLEX® maintenance, repair, and operation (MRO) adhesives and sealants to ensure the reliability of their equipment at all times. The Chemence® line of MRO adhesives has been designed to help professionals prevent common failures, extend equipment life, and increase production reliability. The Chemence® line of KRYLEX® threadlockers, thread sealants, gasket makers and retaining compounds are a valuable addition to any maintenance professional’s toolbox The most common use for KRYLEX® MRO adhesives is to prevent premature equipment failure. Regular use of our maintenance, repair, and operations adhesives in preventative maintenance can alleviate issues that occur regularly in the workplace.

Maintenance and Repair Solutions

Hover over the targets to read more information

Threaded Fastener Loosening

Threaded Fastener Loosening

Threaded Fastener Loosening

Fatigue failure, vibration, thermal cycling, and shock can all cause nuts and bolts to loosen prematurely. A few drops of the appropriate KRYLEX® threadlockers can help maintain clamp load and prevent failure while still allowing for disassembly when needed.

Leaks from Threaded Fittings

Pressure changes, thermal cycling and vibration can all result in leaks on equipment that carries fluids. In addition to production downtime, these issues can lead to costly spills and safety hazards. Application of KRYLEX® thread sealant onto the threaded fitting will eliminate leaks and keep fluids on the right side of the equipment walls much longer than PTFE tape or messy greases.

Alignment Issues

Whether mounting cylindrical fittings or fixturing flanges in place, KRYLEX® threadlockers, retaining compounds and gasket makers ensure that assemblies are correctly aligned and maintain tight seals until they are ready to be disassembled. This prevents premature wear on fixtures and extends product life and reliability.

Threaded Fastener Loosening

Fatigue failure, vibration, thermal cycling, and shock can all cause nuts and bolts to loosen prematurely. A few drops of the appropriate KRYLEX® threadlockers can help maintain clamp load and prevent failure while still allowing for disassembly when needed.

Leaks from Threaded Fittings

Pressure changes, thermal cycling and vibration can all result in leaks on equipment that carries fluids. In addition to production downtime, these issues can lead to costly spills and safety hazards. Application of KRYLEX® thread sealant onto the threaded fitting will eliminate leaks and keep fluids on the right side of the equipment walls much longer than PTFE tape or messy greases.

Alignment Issues

Whether mounting cylindrical fittings or fixturing flanges in place, KRYLEX® threadlockers, retaining compounds and gasket makers ensure that assemblies are correctly aligned and maintain tight seals until they are ready to be disassembled. This prevents premature wear on fixtures and extends product life and reliability.

Benefits of Krylex MRO Solutions

Benefits of Krylex® MRO Solutions A proactive maintenance approach, along with the right products, can keep your plant running more efficiently for longer. Missing repair dates, or scheduling maintenance too far apart, can lead to breakdowns and downtime. Even the most seasoned and knowledgeable repair teams require the right materials to augment their maintenance processes. Our proactive maintenance solutions help find and solve problems before they lead to downtime and increased costs. KRYLEX® MRO adhesives prevent premature equipment failure. Regular use of our maintenance, repair, and operations adhesives can help your business:

- Develop a more proactive approach

- Reduce costly downtime

- Enhance reliability of operations

- Lower overall operating costs